Introduction

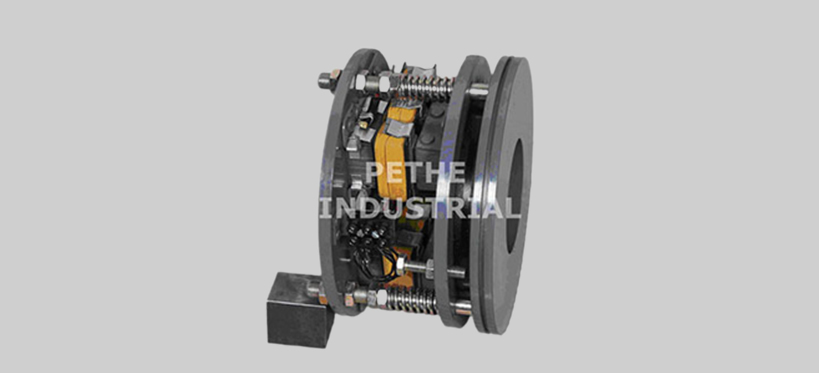

These brakes are also called Normally ON type, failsafe spring loaded disc brakes. Very compact and modern in design. Foundation is not necessary as they are mounted directly on the non-driving end shaft of the motor. It consists of liner plates (friction disc) with square hole at the centre. One corresponding piece of square hub is supplied with the brake. This hub is keyed to the motor shaft and liner plate is free on the hub. Normally, liner plate is gripped between two discs with the help of spring pressure.

When current is supplied to the brake, one disc is attracted by electromagnet against spring pressure and the liner plate is released. Thus the brake is OFF. Once the brake is set it does not require adjustment or maintenance. When the liner plate wears with the use, then only air gap is required to be maintained periodically. Arrangement to release the brake manually is also provided

Range :

- Torque Capacity : 2 Nm to 200 Nm

- Brake diameter 130mm to 320mm

Application :

- All Material Handling and Lifting Equipments

- Hoisting : electric wire rope Hoists and Crabs

- Cross travel and Long travel : EOT / Gantry / Goliath / Derrick Cranes

- Winches and Conveyors

- Lifts and Elevators

- Machine Tools

- Wire drawing machines

- Rubber mixing mills

- Rolling mills

- Sugar, Mining, Cement, Textile industries to name a few.

- Brake Motors

Electromagnetic Disc Brake (A.C.) supplier and manufacturer

Pethe Industrial Marketing Company Pvt. Ltd. is the leading manufacturer and supplier of Electromagnetic brakes in Mumbai, Maharashtra, Gujarat, Delhi, Pune, Bangalore, Chennai, Ahmedabad, Kolkata, Baroda, Hyderabad, Latur, Nagpur, Udaipur, Telangana, Vijaywada, Surat, Rajkot, Bhopal, Coimbatore, Raipur, Ranchi, Faridabad, Noida, Ghaziabad and all over India